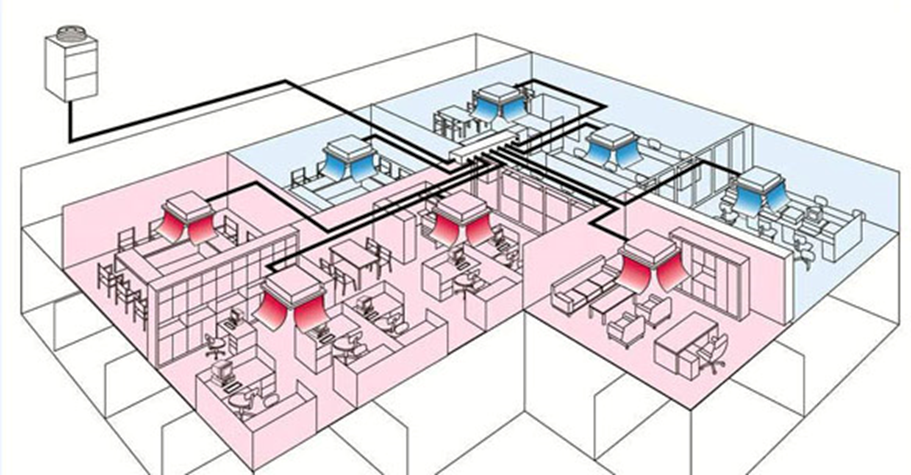

VRF stands for Variable Refrigerant Flow. It is an air conditioning system in which more than one indoor unit is controlled with an outdoor unit. A VRF Air Conditioning System controls the flow of refrigerant based on the building’s changing capacity needs. The VRF Air Conditioning System consists of the outdoor unit outside the building and the indoor units used to cool and/or heat the living spaces inside the building.

The biggest feature that distinguishes VRF Air Conditioning Systems from classical split air conditioners is; Thanks to its variable gas flow rate, it works together with energy saving and keeps the comfort of the users at the highest level. With maximum care and respect for the environment, the system provides enhanced application flexibility focused on energy savings. From a multi-storey plaza to a single villa, it provides full independent control in any new or existing building.

VRF Air Conditioning Systems; Equipped with advanced control and flow control units. The required amount of refrigerant is delivered to the place where it is needed at the right phase and at the right time, so that it is used in heating and cooling. VRF Air Conditioning Systems; It can optionally be connected to an outdoor unit with different HP capacity range and more than one indoor unit in a refrigerant line from conventional split air-conditioning systems.

The refrigerant flow is diversified with an inverter-controlled compressor or compressors, ensuring that the refrigerant adapts to the air-conditioned spaces. An advanced control system switches between heating and cooling modes.

VRF Air Conditioning Systems have 2 different types of systems. Heat Recovery VRF (both heating and cooling at the same time) Heat Pump VRF (only heating or only cooling at the same time) VRF Air Conditioning Systems; It is successfully used in places where independent ventilation applications are required such as offices, shopping malls, luxury apartments, villas, restaurants, plazas, hotels.

Procedures to be done in VRF Air Conditioning Maintenance;

1. Maintenance on Outdoor Units

o External cleaning of the device is done.

o The heat exchanger coil of the device is cleaned.

o In-device gas leaks are checked.

o Internal cleaning of the device is done.

o Electrical supply connections are checked.

o Connections of communication cables are checked.

o The electrical connections of the fans are checked.

o Mechanical connections of fans are checked.

o The electrical connections of the compressors are checked.

o The socket connections of the electronic cards are checked.

o Electrical connections of solenoid valves are checked.

o The electrical connections of the pressure sensors are checked.

o Electrical connections of expansion valves are checked.

o Functions of safety elements are checked.

o Electrical connections of safety elements are checked.

o The functions of the sensors are checked.

o The electrical connections of the sensors are checked.

2. Maintenance in Indoor Units

o External cleaning of the device is done.

o Filter cleaning of the device is done.

o In-device gas leaks are checked.

o Internal cleaning of the device is done.

o Electrical supply connections are checked.

o Connections of communication cables are checked.

o Mechanical connections of fans are checked.

o The socket connections of the electronic cards are checked.

o Electrical connections of the expansion valve are checked.

o The functions of the sensors are checked.

o The electrical connections of the sensors are checked.

3. Devices Working

o The operating values of the devices are recorded.

o Compressor discharge gas temperatures,

o Compressor suction temperature,

o High and low pressure values,

o Condensation and evaporation temperatures,

o Fault lamp and codes,

o Working positions,

o Working conditions of indoor units,

o Electrical data of the system is recorded

WARNINGS

-> Maintenance performed by unauthorized services can cause irreversible malfunctions in the systems.

may cause.

-> Services that are not familiar with the technical details of VRF systems,

will cause it to not work at performance values.

-> Maintenance of VRF systems by authorized services

Allows computer recording. These historical records

It is important for appropriate interventions in possible malfunction situations.